Bentley Motors announced the luxury automotive marque’s financial results for 2021, complementing the company’s record sales performance during the same 12-month period. Operating profits rose to €389 million, which was €369 million more than in 2020.

Turnover last year reached €2.845 billion, while an increased level of personalisation and a model mix dominated by Speed, Mulliner and Hybrid models resulted in the average revenue per luxury car rising by eight per cent over 2020. This contributed to an impressive return on sales of 13.7 per cent.

Bentley had already announced that it had delivered 14,659 luxury cars in 2021, a 31 per cent increase on the previous record year of 2020. Furthermore, there was a steady increase of customer interest in new models resulting in an order bank at record levels at the start of 2022.

The figures are also a vindication of customer appreciation of the freshest model line-up in the luxury segment and of Bentley’s Beyond100 strategy, to be end-to-end carbon neutral by 2030. The initiative has been underpinned by a ten-year investment programme at the Crewe factory, a €3 billion sum representing the biggest transformation and investment programme in Bentley’s history. The company plans to build one new electric model each year for five years from 2025 onwards, as the entire model range undergoes electrification.

“These results were achieved against a continued backdrop of economic uncertainty. They represent a major achievement for everybody involved at Bentley Motors, as we push forward with our Beyond100 programme to reinvent our entire product range in the build-up to carbon neutrality by 2030.” – Adrian Hallmark, Chairman and CEO of Bentley Motors.

“Brand strength has been key to Bentley’s financial performance in 2021, with new models such as Bentayga Hybrid helping to drive profit to a record €389 million. Increasing demand for our hybridised models, supported by €3 billion of sustainable investment in our Crewe factory, will ensure we remain the benchmark manufacturer in sustainable luxury mobility.” – Jan-Henrik Lafrentz, Member of the Board for Finance and IT, Bentley Motors.

Bentley also expands 3d printing capability to produce thousands of new components

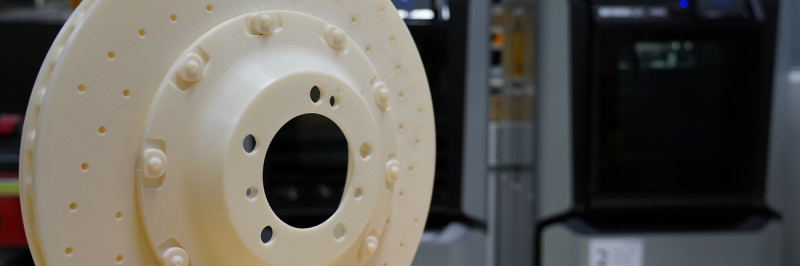

Bentley Motors has shared details of the impact of a £3 million investment to double its Additive Manufacturing (AM) capacity at the company’s headquarters in Crewe, England, where all Bentley models are built. A state-of-the-art AM facility has been applied to a wide range of uses, producing more than 15,000 components in 2021 alone. This expansion will also enable Bentley to utilise advanced technology to create 3D printed vehicle components and even greater personalisation in customer cars.

The AM systems convert 3D CAD models into physical components and is recognised as one of the fastest developing technologies in the world. Bentley’s innovative research and development team has already identified a wide variety of items to print, including on-the-job assisted tools for manufacturing colleagues, such as lightweight sanding blocks in Bentley’s iconic wood shop. Additionally, historically accurate tooling equipment needed to make parts for the Bentley Blower Continuation model was created, and even face shields provided to the healthcare sector due to the COVID-19 pandemic.

AM has been employed to create physical components for several prototype Bentleys, including full-scale powertrain models and aerodynamic wind tunnel models. The advanced techniques have also been used to produce parts for the record-breaking Bentley models that were driven in the demanding Pikes Peak Challenge in America.