AeroDelft team, just revealed a prototype called Phoenix PT. The brand new aircraft is bringing the team one step closer to achieving sustainable aviation.

The student team AeroDelft has revealed the finished structure of their prototype airplane powered by liquid

hydrogen, called ‘Phoenix PT’. The hydrogen airplane does not produce any harmful emissions to the environment.

The finished airplane is an important milestone after two years of dedicated research and production. “This is really

a Christmas present feeling,” says Sam Rutten, who managed the prototype production, during his presentation. Via

various test stages, the team will work towards the first liquid hydrogen flight this fall.

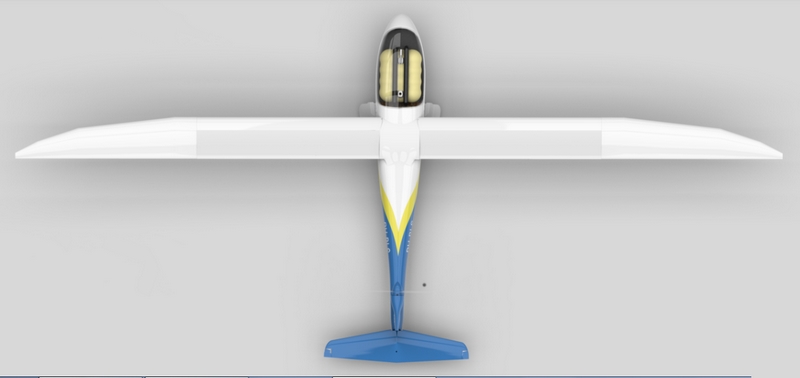

The airplane, showing much resemblance with a glider, is coated in the team’s blue and white colours, with the

logos of sponsors across the body.

AeroDelft, a team consisting of 50 students with 17 different nationalities, wants to prove and promote liquid

hydrogen as an alternative to conventional aviation fuels, to inspire the aviation industry to make the change on a

scale that will result in worldwide sustainable aviation. This puts the team on the frontline of a ‘revolution’ in the

industry, with several initiatives popping up around the world that support the same cause.

A revolution does not come without challenges.

“As the corona pandemic has hampered the process, forcing most work to be carried out from home, it has not been an easy ride,” says Team Manager Jan-Willem van Zwieten. When the pandemic started, the team experienced a major setback, as it lost access to its original workshop. For a number of weeks, the team even had to continue working on the plane from a backyard shed. Nevertheless, through determination the team has been able to make the desired progress and is proud of what it has now achieved.”

There are also challenges lying outside the team that have to be addressed.

Along the production chain of hydrogen, many improvements need to be made in order to efficiently and sustainably produce it at a large scale. The challenges lie in the production, storage and transport of hydrogen. For example, the use of hydrogen in aviation will only be sustainable when the hydrogen is produced sustainably, meaning that it must be produced with green electricity. Additionally, the infrastructure to provide hydrogen to airports at a large scale is still lacking. This highlights the importance of project Phoenix, as small scale innovations like these could spark the development across sectors.

The next step will be to take the aircraft to the skies, requiring the internal components that power the propellor, as

well as certification of the plane to be finished. As the engineers working on these components, such as the

hydrogen tank, fuel cell and motor, are rounding up production, the testing phase will commence. This spring, the

team aims to perform the first battery electric flight with the prototype. In the summer, the first flight on gaseous

hydrogen is planned to take place. Finally, in fall, the team wants to make the maiden flight on liquid hydrogen.

Overall, the team is positive about the future. ‘Now that we have an actual plane, the team’s motivation is rekindled

and everyone is ready for the challenges to come,’ Rutten says. With their plane, the students from AeroDelft will

ultimately be able to fly from Delft to Ibiza on one tank without producing any harmful emissions. A promising

prospect, that well matches their motto: ‘Our future flies in clean skies’.